Introduction

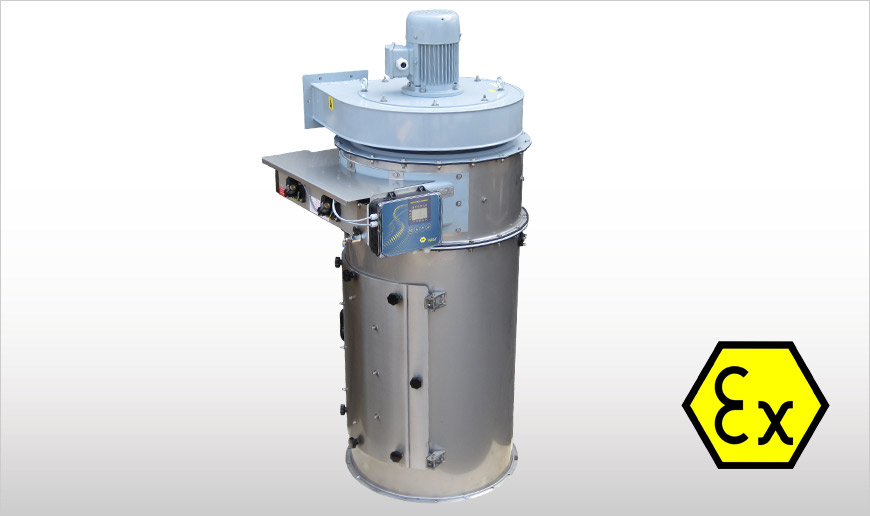

The WAMFLO ATEX Dust Collector range, certified according to the standard ATEX Directive, is designed for use in applications where a potentially explosive atmosphere is present.

Thanks to the various choices in terms of volume, filter surface, filter elements and media, these collectors are suitable for application in a variety of industrial sectors such as feed, foods, plastics & chemicals and others.

Easily adaptable to a wide range of dusts and applications

Operator and plant safety

Technical Specs

Description

WAMFLO ATEX Dust Collectors are designed in accordance with the essential health and safety requisites for equipment meant to be used in potentially explosive atmospheres (ATEX Directive).

They are equipped with a cylindrically shaped stainless-steel casing and flanged bottom ring, which may contain vertically mounted filter elements of various types, such as bags, cartridges and high-efficiency POLYPLEAT.

A compressed air pulse-jet filter element cleaning system is integrated into the hinged top cover or fixed on the connecting top flange.

Increased thickness of the casing improves resistance against explosion.

WAMFLO ATEX Dust Collectors are available with or without suction fan. They come with an integrated modular electronic control panel able to manage cleaning cycles according to the specific requirements of the work process.

Function

The function of the dust collector is to separate dust particles carried in suspension by an air flow using bag-type or pleated filter elements. The dusty air current passes through the filter media, which holds back the dust particles, allowing the air to flow through.

WAMFLO Dust Collectors are configurable for venting, suction and vacuum applications.

Features

- Filter surface: 1 ~ 48 m² (11 ~ 517 sq ft)

- Air volume: 60 ~ 6,000 m³/h (35 ~ 3,530 cfm)

- Filter elements: round bags, elliptical bags, cartridges, POLYPLEAT

- Compressed air pulse-jet cleaning (4 ~ 6 bar)

- Dust temperature from -20 ~ 80 °C (-4 ~ 176 °F)

- Sturdy, compact 304 stainless-steel design

- Multi-voltage and multifunctional electronic control panel

- Quick and safe filter element replacement from clean or dirty air side

- ATEX-version for Zone 22 (Category 3D) or Zone 21 (category 2D)

- ATEX reduced pressure (PRED = 1 barg)

- Suitable for application in internal Zone 20

Benefits

- ATEX certification

- Low emission level due to WAM filter elements and media (BIA/IFA-certified)

- Anti-corrosion design

- Increased work safety

- Advanced operation control with FILCONTROL CONNECT

- Easy, quick installation and maintenance

- Interchangeability with standard WAMFLO as a whole

- Worldwide after-sales service and spare parts provided by WAM subsidiaries

Options

- Fan or connecting flange for centralised dust suction

- Insertable and/or vacuum versions available

- 304 / 316 stainless-steel casing and seal frame

- Large maintenance door

- Advanced electronic multi-control panel and differential pressure meter (MDPE)

- Pneumatic timer

- ATEX explosion relief panel or appropriate pre-arrangement

- Winter protection for solenoid valves

Accessories

- Dust collecting hopper with flow aid, butterfly valve and bucket

- Flanged bottom ring

- Choke valve

- Elbow for lateral connection